Flansa plata pentru teava Transair Ø63, Ø76, Ø100, Ø168

Se utilizeaza impreuna cu garnitura tip EW05 si setul de suruburi de prindere EW06

Tabel de selectie garnituri si kituri de suruburi pentru asamblarea flansei:

| Transair® | Ø D/C | DN | Garnitura | Kit de suruburi | Nr kituri | Cuplu max strangere |

| RA30 63 00 | 63 | 65 | EW05 63 00 | EW06 00 03 | 1 kit | 80 Nm |

| RA30 L1 00 | 76 | 80 | EW05 L1 00 | EW06 00 03 | 1 kit | 80 Nm |

| RA33 L1 24 | R3" | 80 | EW05 L1 00 | EW06 00 03 | 1 kit | 80 Nm |

| RA33 L3 24 | R3" | 100 | EW05 L3 00 | EW06 00 03 | 1 kit | 80 Nm |

| RA30 L3 00 | 100 | 100 | EW05 L3 00 | EW06 00 03 | 1 kit | 80 Nm |

| RA31 L8 00 | 168 | 150 | EW05 L8 00 | EW06 00 08 | 2 kituri | 200 Nm |

| RA30 L8 K2 | 168 | 200 | EW05 K2 00 | EW06 00 08 | 3 kituri | 200 Nm |

- Fisier : Deschide

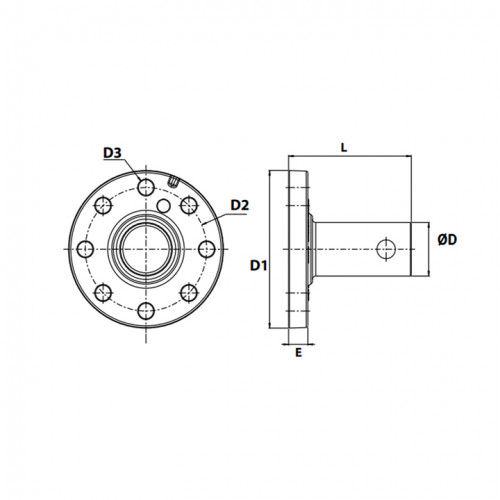

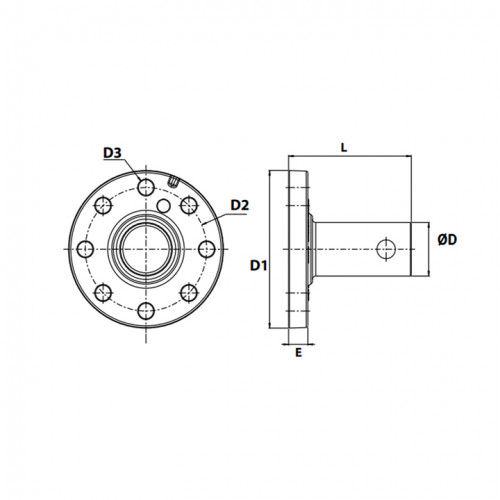

| Cod | ØD mm | DN mm | ØD1 mm | ØD2 mm | ØD3 mm | E mm | L mm | Stoc | Cerere oferta |

|---|---|---|---|---|---|---|---|---|---|

| RA30 63 00 | 63 | 65 | 185 | 145 | 18 | 23 | 146,5 |

|

Adauga |

| RA30 L1 00 | 76 | 80 | 200 | 160 | 18 | 24,6 | 106,8 |

|

Adauga |

| RA30 L3 00 | 100 | 100 | 220 | 180 | 18 | 24,6 | 106,8 |

|

Adauga |

| RA31 L8 00 | 168 | 150 | 279 | 240 | 22,7 | 25,4 | 127,4 |

|

Adauga |

| RA30 L8 K2 | 168 | 200 | 340 | 295 | 22 | 29,3 | 199,3 |

|

Adauga |