Conector rapid drept pentru teava Transair, cu filet exterior conic si placa de fixare pe perete.

- Racordare rapida

- Design cu trecere directa (full bore): diametru interior adecvat atat pentru tevi, cat si pentru racorduri

- Interschimbabil (se aplică Ø 16,5, Ø 25 și Ø 40) si reutilizabil

- Materiale neinflamabile (standardul UL94-HB)

- Presiune maxima de lucru: 16 bari (temperaturi: -20°C ... +45°C)

- Presiune maxima de lucru: 13 bari (temperaturi: -20°C ... +60°C)

- Presiune maxima de lucru: 7 bari (temperaturi: -20°C ... +85°C)

- Temperatura: -20⁰C ... +85⁰C

- Vacuum: 755 mmHg

- Fisier : Deschide

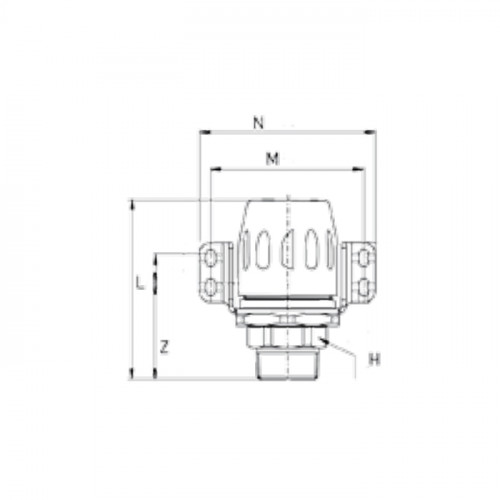

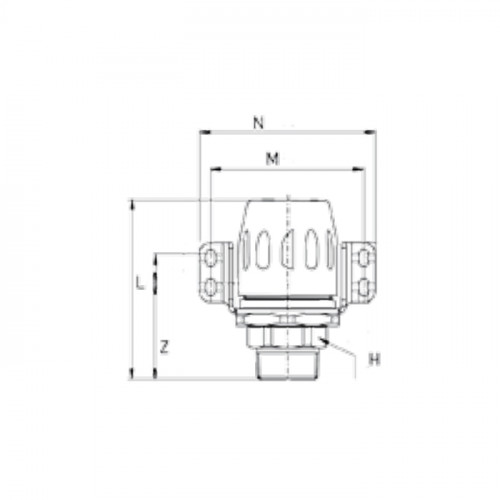

| Cod | ØD mm | C | H mm | L mm | M mm | Z mm | N mm | Stoc | Cerere oferta |

|---|---|---|---|---|---|---|---|---|---|

| 6615 25 21 | 25 | R1/2 | 27 | 87 | 87 | 60 | 102 |

|

Adauga |

| 6615 25 27 | 25 | R3/4 | 27 | 87 | 87 | 60 | 102 |

|

Adauga |

| 6615 25 34 | 25 | R1" | 34 | 91 | 87 | 64 | 102 |

|

Adauga |

| 6615 40 42 | 40 | R1”1/4 | 50 | 121 | 105 | 75 | 120 |

|

Adauga |

| 6615 40 49 | 40 | R1”1/2 | 50 | 121 | 105 | 75 | 120 |

|

Adauga |

| 6615 50 49 | 50 | R1”1/2 | 50 | 127 | 116,5 | 67 | 132 |

|

Adauga |

| 6615 50 48 | 50 | R2” | 60 | 131 | 116,5 | 71 | 132 |

|

Adauga |