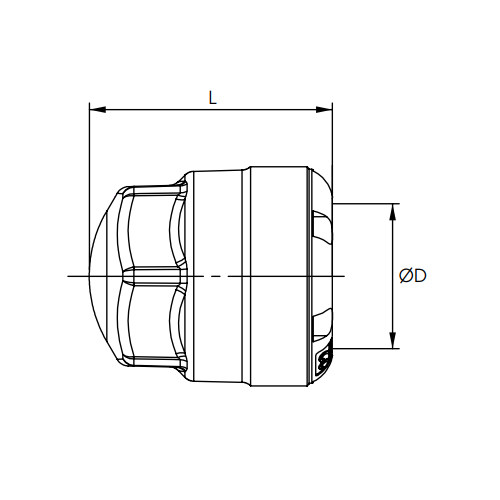

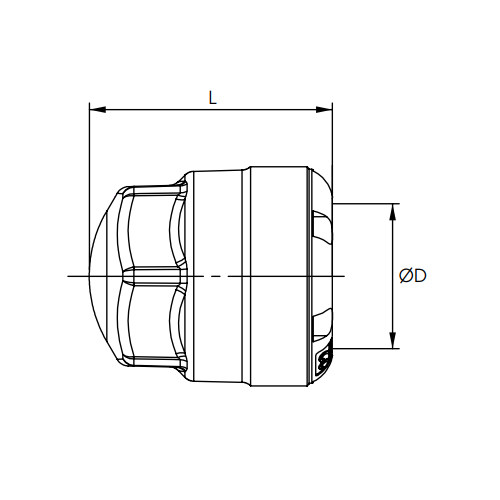

Racordurile de capat (dopuri sau capace) pentru Ø22 și Ø28 pot fi racordate imediat la teava de inox Transair® – teava se va impinge in racord până la marcaj.

Inelul de prindere al fiecarui fiting se securizează astfel automat, si racordul este astfel sigur conectat.

- Fisier : Deschide